High Speed Doors

High Speed Doors are Door systems, mainly used in industrial applications. They are technical enhancements of the generally known sectional door, PVC fabric doors or roller shutter. The main difference is that the durable construction provides a higher operating speed and they are able to sustain a higher number of cycles (opening and closing cycles) and require lower maintenance and repair cost. Depending on the intended field of application, horizontal or vertical operating door types are available.

In North America, the Door and Access Systems Manufacturing Association (DASMA) defines high-performance doors as non-residential, powered doors, characterized by rolling, folding, sliding or swinging action, that are either high-cycle (minimum 100 cycles/day) or high-speed (minimum 20 inches(508 mm)/second), and two out of three of the following: made-to-order for exact size and custom features, designed to be able to withstand equipment impact (break-away if accidentally hit by vehicle) or designed to sustain heavy usage with minimal maintenance.

Application

The High Speed Doors are usually used wherever goods traffic occurs and where the doors have to fulfill special requirements. In the food and beverage industry Medial industry for example, special climatic conditions have to be prevailed. Short opening and closing times reduce cooling loss, avoid airflow and enable a smooth operating procedure. It can also be design for big dimension doors for mining and aircraft industry

As an Architectural feature: Often, buildings are required to satisfy particular aesthetic demands. Due to their modern and variable look, some high-speed doors perfectly match every kind of architecture. In addition, the door also meets the particularly critical demands regarding noise insulation as well as the requirements with regard to heat insulation. A special high speed parking system door was developed for this application.

In the beverage industry: Intelligent airlock solutions can be achieved by means of high-speed doors. Two doors with the highly transparent laths gives a clear view throughout. Pressure and temperature differences can easily be controlled by an airlock where the transporter enters the airlock, with the one door cannot be operated before the other has closed. This is also used in security application.

In food, clean, and pharmaceutical processes: In strict environmental constraints of pharmaceutical and aggressive environments of the food processes, where hygiene is imperative, doors must not only provide a structure made of stainless steel or composite materials to prevent corrosion, but they must also ensure an exposure time as short as possible to reduce the risk of airborne contamination.

In the car manufacturing industry: The automotive industry is the industry where high speed doors are the most well known. High volumes of cars are produced in short periods of time. High speed doors are vital for the logistics processes, high speed and low maintenance ensures optimum production. A special high speed folding door are used on the dynamo tuning cells.

Profitability: High-speed doors by increase the efficiency of every company. High opening speeds minimize the waiting time in front of the doors and thus accelerate the logistic processes, controls temperatures and pressure differences while saving energy. Isolating clean areas from airborne contamination but still optimizing traffic flow.

Requirements

High strains, caused by the high operating speed (up to 4m/s)(str) and the frequency of openings, have to be taken into account during construction. In the same way, basic conditions like size and installation location add up to considerable requirements regarding safety and control technique.

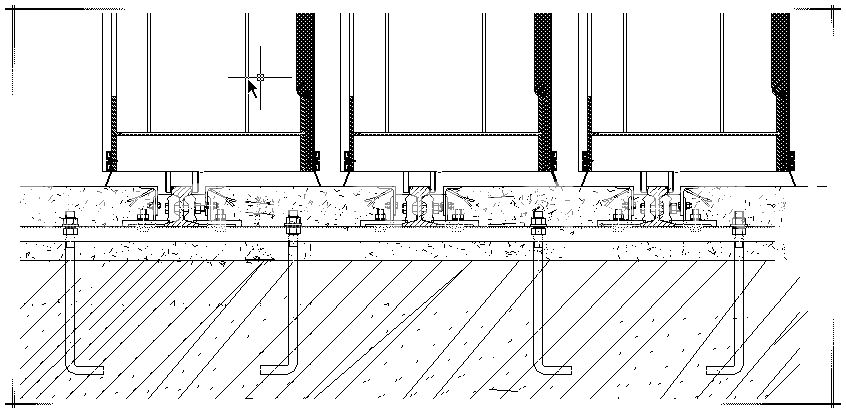

A unique "roll-up" system generally defines a high speed door from an conventional roller door. The doors main objective is to produce a high opening speed and the guiding system must allow smooth operations with minimal friction. Effortless movement will ensure the longevity of the doors moving parts and operating soundness. Latest versions of high quality high speed doors uses a spiral guiding system, thus keeping the door blade apart through a whole operating cycle, ensuring effortless movement of the doors roller devices in the guiding system and contributing to the excessive high speed.

A counterbalance system generally forms part of the doors construction. This is designed with spring or weight mechanisms in the side frames, ensuring an emergency opening function and aiding to the opening speed.